Flexible welding workbench is also known as 3 D flexible welding workbench, 3 D welding table, 3 D welding plate, 3 D flexible welding plate, flexible welding table. The product is very flexible and can withstand a very high load capacity. All five sides are processed with regular holes and eng...

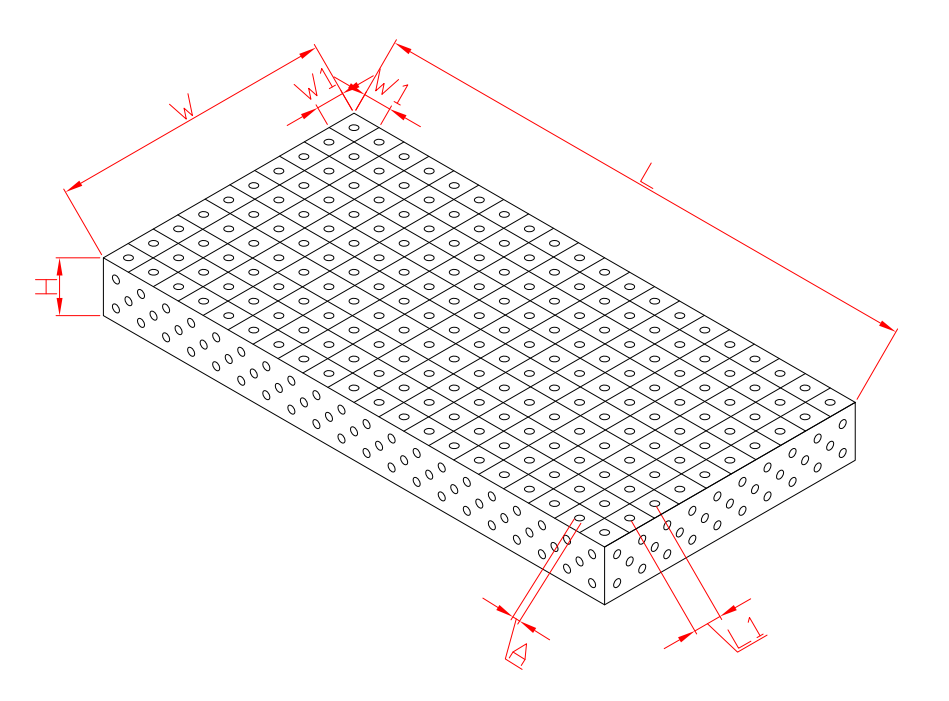

Flexible welding workbench is also known as 3 D flexible welding workbench, 3 D welding table, 3 D welding plate, 3 D flexible welding plate, flexible welding table. The product is very flexible and can withstand a very high load capacity. All five sides are processed with regular holes and engraved with grid lines.(No slope and T-shaped groove). On a 3 D flexible plate, any workpiece can be positioned and clamped in a variety of ways by positioning the clamp pin (PC pin / lock pin). This PC pin is specially designed. Multiple 3 D workstations can be arbitrarily directly connected together in one of the five sides. This modular system embodies universal functionality in installing, adjusting, and clamping workpieces. Its advantages are especially reflected in the application of large workpieces. During assembly or welding, the flexible welding tools use positioning blocks, connection blocks, fixtures, and support blocks to locate the workpiece and hold it firmly to each positioning point or positioning surface. In the welding process of flexible welding bench, only use low-cost splash-proof liquid to avoid the surface of welding slag. The experimental platform has been aged. Through the interchangeability of the modular design, complex and complex clamp combinations can be completed in a short time. It is very economical whether to make a single part or to assemble it. Grid holes on the workbench surfaceAnd the mesh holes on each module achieve high precision and reproducible clips. First, it is a set of prefabricated standardized, systematic and universal modules. All modules are connected, fixed and tightened by hole positioning and locking pins. The module can be replaced according to the size of the workpiece. Through adjustment, the whole fixture can be combined in three-dimensional space. The characteristics of this set of fixture are: mainly used for welding, so it is called 3 D flexible welding platform and flexible welding fixture. This clamp is divided into two parts:

1) The series is divided into two series: D16 and D28;

2) According to the material, it is divided into: steel parts 3 D flexible platform and casting 3 D flexible platform;

It is the basic platform of 3 D flexible assembly tooling, and its role is to support the processed workpiece and positioning fixture, pressing fixture, calibration and treatment tool, etc.

The hole distance of D28 series platform is 100mm, all platforms are engraved with corresponding grid lines, and 100×100 grid lines are engraved on the workpiece installation surface of the table to facilitate visual inspection of the workpiece.

The hole distance of the D16 series platform is 50mm, with corresponding grid lines engraved on the platform, and 50×50 grid lines engraved on the workpiece installation surface of the table to facilitate the visual inspection of the workpiece.

According to the customer requirements, the millimeter scale ruler table can be depicted on the two right sides of the platform in the form of grid hole. The platform size is up to 6000x2200mm, and it can also be customized according to the actual needs. It can not only be used as a welding platform, but also as an assembly platform, testing platform, machine tool processing platform, etc.

| Customizable at any size | |

| Specification (L x W x H) | |

| 1000×1000×200mm | 1500×1500×200mm |

| 1000×1500×200mm | 1500×2000×200mm |

| 1000×2000×200mm | 1500×3000×200mm |

| 1000×2500×200mm | 1200×2400×200mm |

| 1200×1200×200mm | 2000×3000×200mm |

| 1200×2400×200mm | 2000×4000×200mm |

| Material: a, HT 30 O casting, b, Q355 steel plate welding, c, high hardness steel plate welding, d, stainless steel steel plate welding | |

| Pore size: A=φ28.065–φ28.149mm. | |

| Hole distance: L1=100±0.05mm. | |

| Line cutting: line spacing W1=100 ± 0.05mm. | |

| Planness: 0.1 / 1000mm. | |

| Verticality: 0.1 / 200mm. | |

| Surface roughness: Ra 3.2. | |

| Bearing capacity: standard type 2T, frame type: 5T. | |

| Hardness: hardness of material body, hardness of nitrous layer: HV 450-HV 630 | |

Flexible welding workbench products are characterized by: affordable, complex and expensive traditional fixture has become the past. You can avoid the high costs of a large inventory of tools, because the 3 D system does not need to be modified to accommodate a variety of workplaces. Such devices are very convenient to operate.